Underground Tank Removal at Pilgrim Nuclear Station

Plymouth, Massachusetts

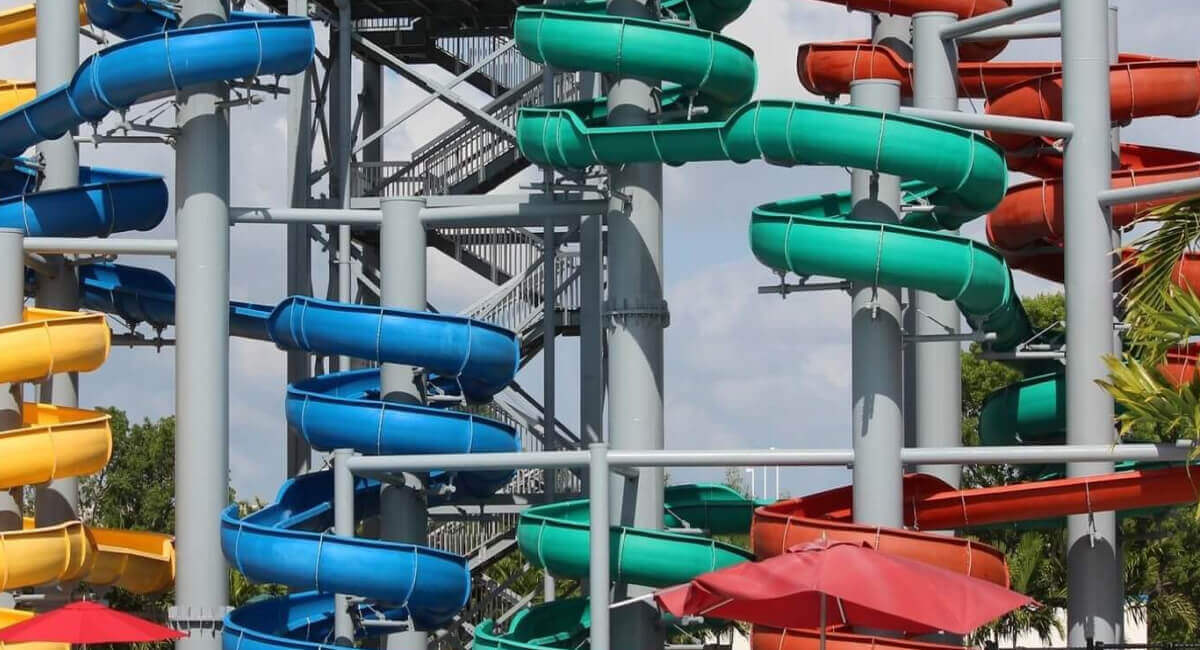

C.B. Smith Water Park, located in Broward County, FL, is home to a sprawling water park composed of four 50-foot-tall water slides, a lazy river, and many other family-oriented outdoor activities. The park is a significant community amenity that offers tennis and waterski lessons and hosts many seasonal festivals. The park’s owner, Broward County, recently engaged Champion to protect and preserve its slides by cleaning, blasting, and coating the structural steel and rehabbing the slide interiors.

The C.B. Smith Slides project was completed in two phases: first, preparing and coating the structural steel and then preparing and coating the interior slide surfaces.

The structural steel phase involved pressure washing at 3,500 psi to remove all direct and surface contaminants in accordance with SSPC-SP12 and WJ4 standards. Following the power wash, the steel was wet-abrasive blasted using SSPC-SP16 protocols. The steel was then inspected for blast cleanliness and to ensure a 2 mil surface profile. After the inspection, Champion crews applied a full prime coat of SW Zinc Clad 4100 at 3.0-5.0 mils to any area with uncoated steel. Then, SW Sherloxane was applied as a stripe coat to all edges, angles, bolts, and welds. Finally, a full-finish coat of SW Sherloxane was applied to all surfaces at 4.0-6.0 mil thickness. Both conventional and airless sprayers were incorporated, as needed, throughout the coating process.

Fall protection was a priority throughout this phase of the project, which called for an innovative access strategy that combined the use of aerial lifts, spider swing stages, and baskets. The ground below was protected from overspray by the use of ground tarps.

Phase two–gel coating the slide interiors–involved high-pressure water cleaning at up to 4,000 psi using a biodegradable degreasing agent and, when called for, a steam and hot water blast. The joints and crevices required hand scraping, sanding, and wire brushing in accordance with NACE SSPC-SP2 standards. When necessary, these areas were power-tooled with sanders, grinders, and wire wheels, using NACE-SSPC-SP3 protocols. Fresh layers of Fiberglass were applied, as needed, and slide joints were caulked with Sikaflex Adhesion Pre-Prime and Sika Flex 291 White Urethane Adhesive Seal. Open areas of the slides were resurfaced to the recommended thickness of 20-25 mils using Baynum Pigmented Topcoat.

The slide structures were used to access the interior surfaces and a system of cardboard, plastic, and tape was incorporated to provide barriers that prevented material overflow onto other areas. Champion collaborated with a third party, Baynum Amusement Solutions, in order to streamline the gel application process. Baynum was more familiar with the gel material’s characteristics and as a result, the application process was accomplished in the most time-efficient manner.

Expenses were controlled on the C.B. Smith Water Park Slide rehab project by returning rental equipment at the earliest possible time, not allowing coating materials to go to waste, and keeping the Champion crew small. Utilizing a small, experienced crew also allowed employees to leverage their individual expertise while staying focused on delivering the work. Champion used this opportunity to enhance its knowledge of a previously unfamiliar coating system, which will lead to expanded proficiency and greater profitability on future projects.

Date Started: February 2022

Date Complete: March 2023

Project Manager: Jack Spurling

Superintendent: Andy Madonis

Customer: Broward County

Size: 16,000 sf of Structural Steel, 11,437 sf of Gel Coat

Structural Steel

Gel Coating

Blasting/Coating