Underground Tank Removal at Pilgrim Nuclear Station

Plymouth, Massachusetts

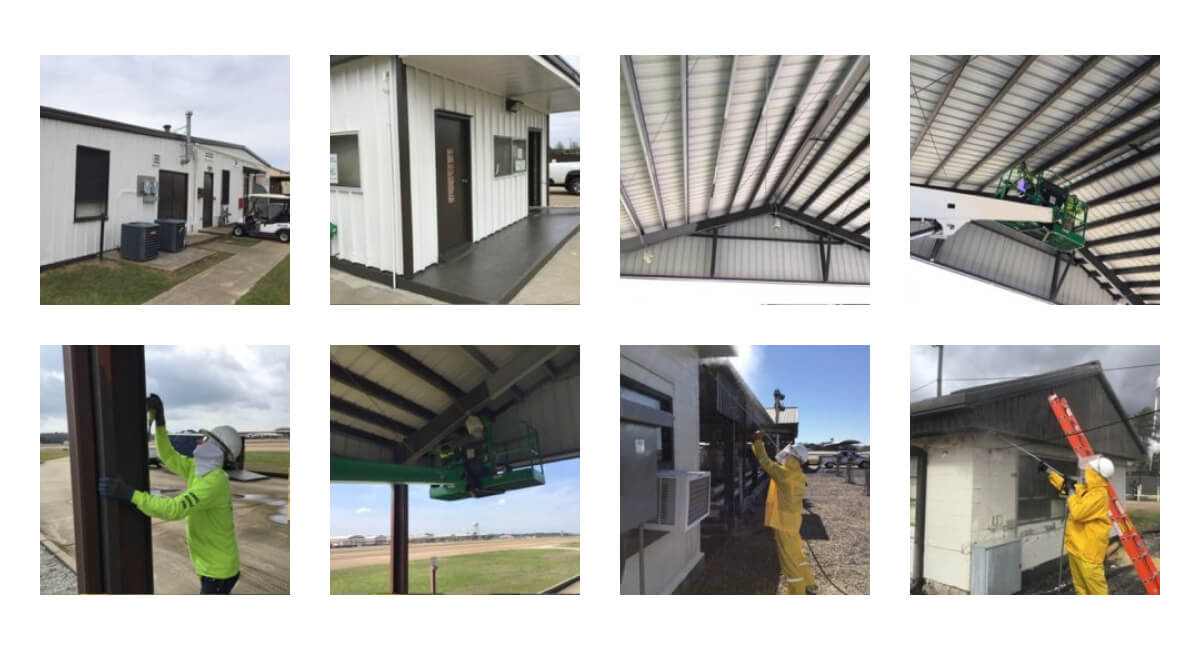

Recurring Maintenance, Minor Repair (RMMR) services for four buildings, one vehicle fuel island, and one awning-covered airfield vehicle fueling station.Total square footage (exteriors): 7,365Champion’s foreman and our quality control team worked with the GC and local base leadership to match unique non-standard color requirements for the airfield fuel facility steel. At that location, our crews used aerial lifts to access structural steel aloft for hand tool surface preparation and brush and roller application, and ensured no impact on flight operations or adjacent fueling stations.

The site was between an active runway and taxiway.

As the project neared completion, we faced the additional challenge of base access and project execution when COVID-19 restrictions were put in place. With the cooperation of Pond Constructors, base leadership, and the independent third-party QP-5 inspector, the Champion crew was able to finish the project ahead of schedule while strictly following all social distancing and hygienic guidelines.

Exterior Surface Preparation (Aluminum Trim on Building 1): SP-7 Wet Abrasive Blast (coal slag)

Exterior Coatings System: Sherwin Williams

Exterior Surface Preparation (Masonry Block on Building 1): Spot SP-3 Power Tool Cleaning

Exterior Coatings System: Two coats of Sherwin Williams HB Fastclad

Exterior Surface Preparation (Aluminum Siding/Trim on Building 2): WJ-4 Water Jet

Exterior Coatings System: Sherwin Williams

Exterior Coatings System: Sherwin Williams

Exterior Coatings System: Sherwin Williams

Two coats of Sherwin Williams HB Fastclad.

Exterior Surface Preparation (Structural Steel on Airfield Awning): SP-3 Power Tool Cleaning

Exterior Coatings System: Sherwin Williams

Date: 6-15-2020

Prepared: Zack Beehner

Project: Coatings Repairs of Buildings and Structures at Columbus AFB, MS.

General Contractor: Pond Constructors

Customer: USACE

Specialty Services

Recurring Maintenance, Minor Repair (RMMR) services

Champion deployed a five-man crew 839 miles from our Southeast region office in Fort Lauderdale, FL to Columbus AFB, MS. Work began on February 22, 2020 and finished on April 6, 2020. Six sites were independently located on the base, which required synchronization of multiple “mini” mobilizations and demobilizations, as well as concurrent execution as dictated by weather conditions to ensure schedule adherence.