Drywell Moisture Barrier Recoating Case Study

Newport, MI

Thomas Industrial Coatings and Champion Industrial Joint Venture

Scope: Surface preparation and coatings of interior and exterior of two 125’ diameter by 52’ tall JP-8 jet fuel tanks and associated exterior piping, in accordance with UFGS 09 97 13.27 (Exterior Coating of Steel Structures) and UFGS 09 97 13.17 (Three Coat Epoxy Interior Coating of Welded Steel Petroleum Fuel Tanks). In addition, the Thomas Champion Joint Venture (TCJV) completed joint replacement and crack repairs in the containment dike areas and full chime replacements.

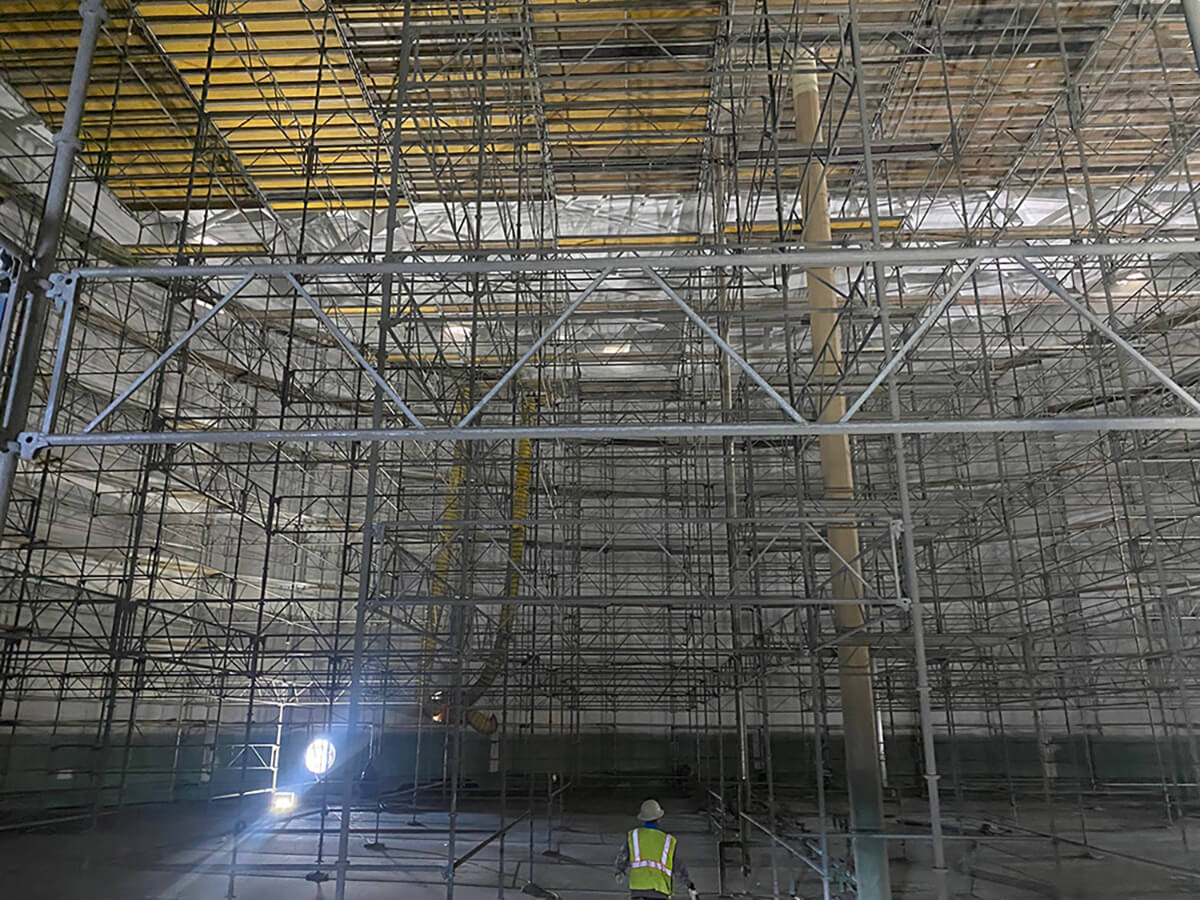

The TCJV deployed a 30 man crew 8,000 miles from CONUS to the Territory of Guam. The first crewmembers arrived in January 30, 2021 and the team finished contractual requirements in September 2021. Full interior and exterior scaffolding was erected by the TCJV team. Non-metallic copper slag abrasive was used by our blast team to achieve the UFGS requisite surface preparation standards in a timely and efficient manner.

Interior work was kept under full dehumidification and temperature control to adhere to UFGS requirements. A variance for a moisture cured system was approved by the U.S. Government, the key to our successful application in Guam’s hot and humid tropical environment.

The TCJV executed this project with the mission statement of “Two Tanks – One Team,” and the successful completion is a direct result of the crews’ ability to work together toward a common goal. When faced with pandemic-caused shipping issues, adverse environmental conditions, outright weather emergencies, and the challenges of operations far from CONUS, the TCJV demonstrated grace under pressure and overcame every challenge.

Concurrently, the entire job was executed in accordance with Federal, Territorial, and Department of Defense protocols to prevent the transmission and spread of the COVID-19 virus, with no incidents.

Exterior Specification: UFGS 09 97 13.27 (variances approved by U.S.G.)

Exterior Surface Preparation: SP-10 Abrasive Blast (copper slag)

Exterior Coatings System:

Interior Specification: UFGS 09 97 13.17

Interior Surface Preparation: SP-10 Abrasive Blast (coal slag)

Interior Coatings System:

Date: 9/20/2022

Prepared by: Zack Beehner

Project: Coatings Repairs of Tanks A-11 and A-12 at Andersen Air Force Base, Guam

General Contractor: Gilbane Federal

Customer: AFCEC

Scaffolding

Coatings

Tank Lining